Research

Fuel Cells as the Basis for the Realization of a Hydrogen Energy Society

We are pursuing the development of materials and processes to be applied to fuel cell and related hydrogen technologies for the realization of an eco-friendly hydrogen energy society. We are working on several projects, including materials development, evaluation of mechanisms in fuel cells, fuel cell systems design and technology, and the development of highly durable systems and materials. We pursue these projects by making full use of 25 years of accumulated knowledge through research in our group.

We have comprehensive experimental systems to carry out exhaustive fuel cell research from fundamental materials evaluation, to fuel cell fabrication equipment, to advanced electrochemical evaluation techniques, exhaust gas analysis, microscopic observation and process simulation. We also have numerous fuel cell evaluation systems (ca.60 systems in our labs) and the highest-level advanced devices such as our super high resolution Scanning Transmission Electron Microscope (STEM). We are actively working on fundamental research, collaborative projects with industry, and demonstration studies.

Fig: The Next-Generation Fuel Cell Research Center (NEXT-FC, right).

Our group runs this center, and more than 10 companies rent lab space inside.

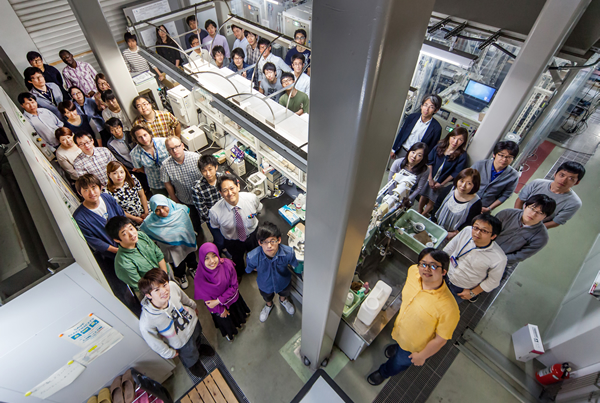

Fig: The members of our laboratory (West 4, 1F).

(1) Development of Electrode Materials and Study of the Processes

in Solid Oxide Fuel Cells (SOFCs)

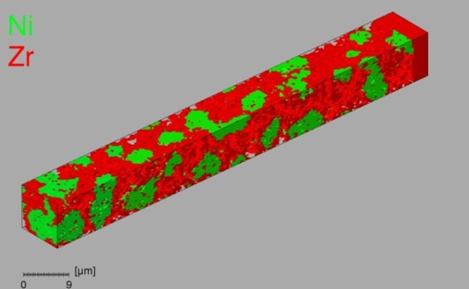

We are developing SOFCs with high performance and durability, and are evaluating the reaction process and thermal stability. We are involved in national research projects on SOFCs, organized by NEDO. We are preparing a database of the effect of poisoning on long-term durability (FY2005-), and evaluating the performance and durability of SOFCs for highly efficient gas turbine systems (triple combined cycle) (FY2012-). [Sasaki, S. Taniguchi, Shiratori, Tachikawa, Matsuda, Oshima, Nagai, Kawabata, Miyara, Uryu, Sugawara et al.]

Fig: 3D FIB-SEM reconstruction of a SOFC anode. Accumulated Ni becomes isolated in the anode electrode after accelerated durability tests. (Sasaki et al.)

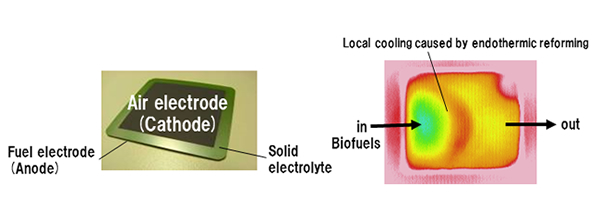

(2) Development of a Biogas-Fueled SOFC

Biogas, generated by anaerobic fermentation of organic wastes, consists of 60% CH4 and 40% CO2. In principle, biogas can be directly fed into a high-temperature SOFC without pre-reforming, to obtain electricity. Our group has demonstrated the long-term stability of an internal reforming SOFC running on biogas, using anode-supported single cells. Currently, the thermo-mechanical reliability of an internal reforming SOFC is being evaluated using a visualization system which enables us to perform in-situ measurements of the temperature distribution. [Shiratori, Tran, Sakamoto, Uchida et al.]

Fig: Anode-supported SOFC and in-situ temperature measurements using hydrocarbon fuel at the anode.

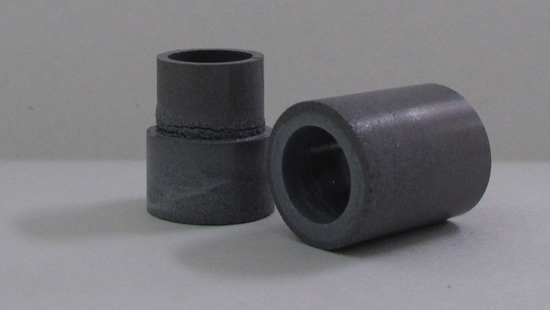

(3) Development of a Metal-Supported SOFC

We are developing metal-supported SOFCs using a heat-resistant stainless steel as porous substrate. Our target is to realize a novel SOFC which can be operated under high power conditions, maintaining durability against factors such as thermal shock or fuel starvation. (Taniguchi, Park, Inoue et al.)

Fig: Concept of a novel high-power SOFC with porous metal supports (Taniguchi et al.)

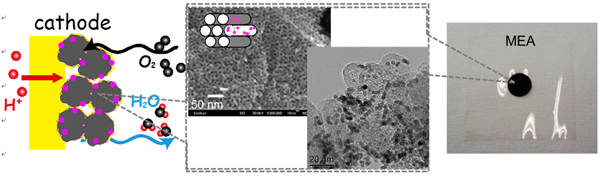

(4) Electrode Materials and Process Research for

Next-Generation Polymer Electrolyte Fuel Cells (PEFCs)

We have been working on the development of novel PEFC electrocatalysts with high activity and durability, and the nanostructural design of catalyst support materials. In particular, we have succeeded in the development of carbon-free electrocatalysts, leading to a fundamental solution for carbon corrosion problems. (Hayashi, Lyth, Nishihara, Noda, Matsuda, Sasaki et al.)

Fig: Mesoporous carbon-based PEFC electrocatalysts (Hayashi et al.)

Fig: Carbon-free PEFC electrocatalysts (Sasaki et al.)

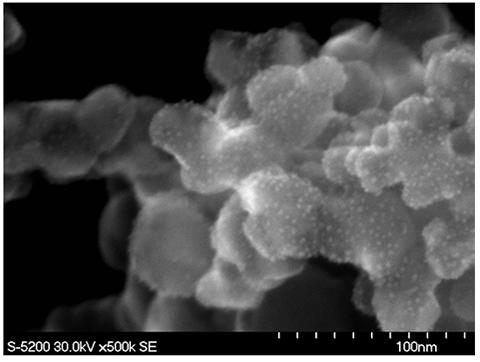

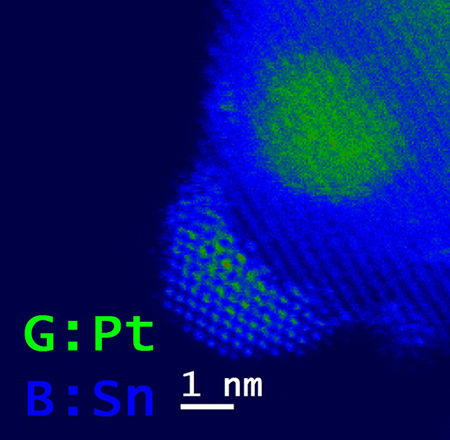

(5) Fuel Cell Design from the Atomic Scale: Development of Scientific Principles and Fundamental Analysis

We aim to develop of engineering techniques related to hydrogen utilization systems such as fuel cells. We are developing fundamental techniques to study defect chemistry, solid state electrochemistry, thermodynamics and mass transport, electrode process, electrochemical evaluation methods and microscopy at the atomic, electron, and molecular levels.

Recently, atomic-resolution and environmental electron microscopy has become crucial for research on a wide range of fuel cell materials. Atomic-level fuel cell design and processing could be possible in the near future. (Matsuda, Sasaki et al.)

Fig: Atomic resolution electron microscopic image of highly durable

oxide-supported Pt electrocatalysts for PEFCs

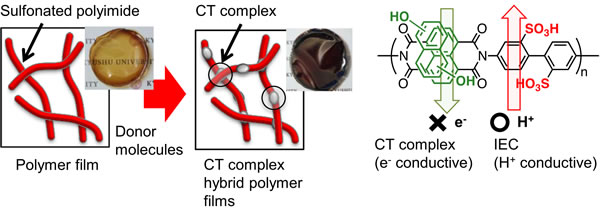

(6) Fuel Cell Design at the Molecular Scale: Development of Novel Polymer Electrolyte Membranes

We are developing polymer electrolyte membranes (PEMs) for high temperature PEFC operation by using material design at the molecular scale. We are studying novel PEMs functionalized by charge-transfer complex formation. The unique characteristics of this method are facile processing and functionalization for preparation of PEMs compared with other methods.

Fig: Schematic image of charge-transfer complex hybrid polymer films.

Proton conductivity is dominant over electronic conductivity. (Nishihara et al.)

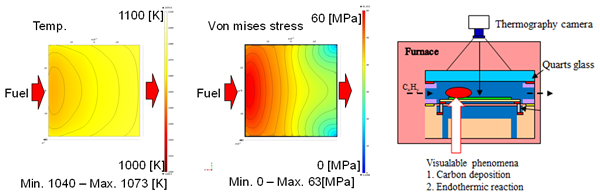

(7) Fuel Cell Design at the System Level: Development of In-Situ Visualization Methods

We have been developing visualization methods for electrochemical reactions at fuel cell electrodes in order to observe electrode micro- and macro- scale structural changes, and to aid in the development of next-generation fuel cells. We are researching experimental methods to visualize the in-situ changes on the SOFC electrode surface, and performing numerical simulations to investigate factors such as thermal stress and electrochemical reactions. System process and heat balance modeling methods are also considered for the evaluation of fuel cell performance at the system scale.

Fig: Temperature and thermal stress distribution on SOFC electrodes via numerical simulation; SOFC in-situ visualization system for experimental research. (Tachikawa et al.)